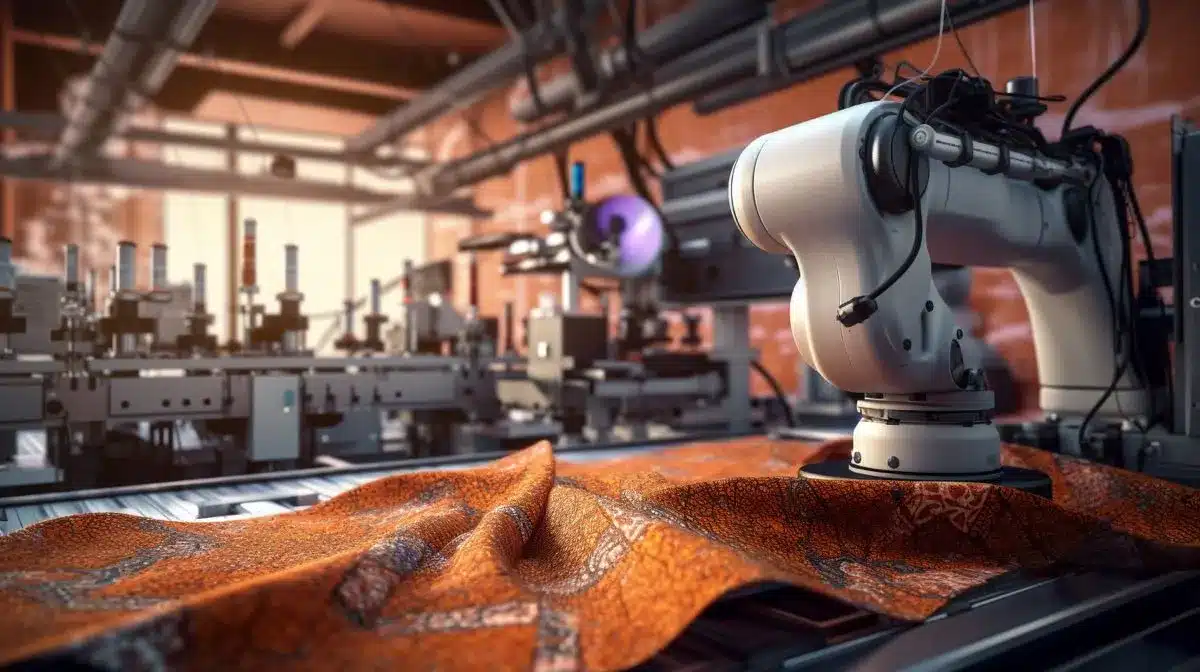

The textile industry is undergoing one of the most important changes in its history. While traditional manufacturing methods have served the industry for decades, the arrival of Artificial Intelligence (AI) and the Internet of Things (IoT) is revolutionizing the way fabrics are designed, produced, and delivered.

This transformation is not just about speeding up production. It is about improving quality, reducing waste, and creating more sustainable and responsive supply chains. As global demand for apparel increases and fashion cycles become shorter, textile manufacturers are under pressure to deliver more in less time without compromising on quality. AI and IoT are making this possible.

What is AI in Textile Manufacturing?

Artificial Intelligence refers to computer systems that can process large amounts of data, recognize patterns, and make intelligent decisions without constant human input. In textile manufacturing, AI-powered systems are being used to:

- Detect fabric defects instantly with AI-based vision inspection, reducing faulty output and waste.

- Predict machine maintenance needs before breakdowns occur, preventing costly downtime.

- Optimize production schedules by analyzing historical data and real-time demand forecasts.

- Automate quality control processes to ensure consistent output.

For example, an AI system connected to fabric inspection cameras can spot microscopic weaving defects that the human eye might miss. Instead of having to discard large batches, manufacturers can isolate and correct the problem immediately.

The Role of IoT in Textile Manufacturing

The Internet of Things connects devices, machines, and sensors to share real-time data. In textile production, IoT enables factories to:

- Track production progress at every stage from raw yarn to finished garment.

- Monitor machine performance and energy consumption to improve efficiency.

- Ensure accurate inventory management to avoid overproduction or shortages.

- Enable remote factory management through connected control systems.

For example, IoT sensors installed on weaving machines can send live performance data to a central dashboard. If a machine is running slower than expected, the system can alert maintenance staff immediately.

How AI and IoT Work Together in Textiles

When AI and IoT are combined, they create a fully connected smart factory environment. IoT devices collect huge amounts of production data while AI analyzes it to make instant process adjustments.

- IoT provides real-time visibility into what is happening in the factory.

- AI uses this data to optimize production automatically without waiting for human intervention.

Imagine a dyeing process where IoT sensors monitor water temperature and chemical concentration in real time. AI can instantly adjust these variables to ensure the perfect dye quality for every batch. This not only improves quality but also reduces waste and energy consumption.

Why the Textile Industry Needs This Shift Now

The textile sector is facing challenges like:

- Rising labor costs in manufacturing countries.

- Increased demand for sustainability and transparency from global buyers.

- Shorter fashion cycles and faster order turnaround times.

- Pressure to meet international compliance standards.

Manufacturers that adopt AI and IoT now will have a significant advantage over competitors who continue with purely traditional methods. This shift is no longer optional. It is a requirement for survival in the global apparel supply chain.

The Sustainability Advantage

One of the biggest benefits of AI and IoT in textiles is their contribution to sustainability. By enabling precision manufacturing, these technologies help reduce:

- Material wastage.

- Energy consumption.

- Water usage in dyeing and finishing.

For instance, AI-powered dyeing systems can calculate the exact amount of dye required, avoiding excess use and preventing harmful wastewater discharge. Similarly, IoT-enabled energy tracking can identify inefficient machines, allowing factories to upgrade or repair them for better efficiency.

Real-World Applications of AI and IoT in Textiles

- Smart Fabric Inspection – AI detects weaving errors immediately, preventing defective rolls from being processed further.

- Predictive Maintenance – AI analyzes vibration, temperature, and machine usage data from IoT sensors to predict breakdowns before they happen.

- Demand Forecasting – AI studies buying patterns and seasonal trends to help manufacturers produce the right amount of stock.

- Supply Chain Visibility – IoT trackers monitor shipments from the factory to the retailer, reducing delays.

- Sustainability Monitoring – AI and IoT track energy, water, and chemical use to ensure compliance with environmental standards.

WiMetrix and the Digital Future of Textiles

At WiMetrix, we help textile and apparel manufacturers transition into the era of smart manufacturing with solutions that integrate AI and IoT seamlessly into existing processes. Our technology offers real-time production tracking, predictive analytics, and performance optimization to help factories increase efficiency, meet sustainability goals, and remain competitive in the global market.

AI automates quality control, predicts machine maintenance, and optimizes production schedules to increase efficiency and reduce waste.

IoT connects machines and sensors to provide real-time data, helping factories monitor performance, track inventory, and improve operational transparency.

No. These technologies work alongside humans, helping them focus on high-value tasks while machines handle repetitive or precision-based work.